The light tubes are done

Posted: 2005-August-14 Filed under: Lighting, Projects, The Bike With 2 Brains Leave a comment »I needed to finish up the light tubes today for the demonstration in the afternoon. I wired all the pigtails from the end of the tube into a DB-25 connector. Since I had not labelled the wires, I had to test each LED so I could wire them on the connector in order. Not such a big deal. I got the whole setup mounted on the bike. For the demonstration (since I didn't have the computer finished) I just wired up a couple DB-25's to light up all the blue LED's that face backward. It looked pretty cool, especially at night.

![]()

Demonstration for the musicians

Posted: 2005-August-14 Filed under: Exhibitions, Projects, The Bike With 2 Brains Leave a comment »I invited everyone who provided music or made an effort to provide music to my house to see the bike. Jon Peone (XLTieRack) and Jessica stopped by … I guess the rain drove everyone else away. It was a pain in the butt putting things together in the rain, but at least it was a good test. They thought it was pretty cool although the wet ground was pretty terrible to try and ride on. The sound system was in place with most of the finished music on it … all running off batteries. I was using a mostly-dead 12-volt sealed lead-acid battery (probably with 2 amp-hours instead of the original 7) and it ran fine for about 4 hours, powering both the sound and half the blue LED's (which would be about typical given the light system I plan to use.)

![]()

How to detect if the MP3 player is playing and making an MP3 of my own

Posted: 2005-August-13 Filed under: Audio, Projects, The Bike With 2 Brains Leave a comment »It took me longer than I thought it would, but I finally got a circuit to detect audio output. This is the only way I can tell if the MP3 player is actually playing — the computer will need to turn on the MP3 player and then to set it to play. Anyway, the thing that took a while was doing tests with various capacitors and discharge resistors. I wanted at least 15 seconds of silence before the circuit would indicate silence. In retrospect, I probably should have had the computer handle that, but oh well. It's built now. I also added the LED so I can set the trimpot easier — it might have been a better idea to put in a switch or jumper, but I used a large resistor so the LED only consumes a few milliamps.

The other thing today in audio land was to edit the recording I made the other day and make an MP3. It wasn't too hard although I really have no audio editing software so I had to do it with video stuff. Anyway, it's titled "The Edge Between 15A and 15."

![]()

Debugging the Dead Power Supply

Posted: 2005-August-12 Filed under: Power Source, Projects, The Bike With 2 Brains Leave a comment »I don't think I mentioned it (and am too lazy to scroll down to check) but a friend of mine stopped by the other day and I was showing her all the stuff I've built so far. I loaded the switching power supply with 3 ohms to demonstrate the noise I get, but later I realized the -5 volt output was no longer working … odd. Tonight (Friday, by the way, and yes, I have had a few drinks — a chilled shot of Ouzo, a Saranac Pale Ale, and a Genesee can at home) I checked the power supply and inexplicably, the LM324 died — the op-amp that controlled the pulse-width modulation stayed at the positive rail for no reason. I pulled it and threw it away, even though it might have just as well been a loose connection. Replacing it worked just dandy. I tried connecting every LED — both strings, all three colors — and the input drew 0.53 amps for 0.76 amps out (in power, that's 6.36 watts in for 3.8 watts out for an efficiency of 59.7% — cool: almost 4 watts of output through LED's!) Anyway, I decided that the switching noise wasn't going to be much of a problem. Even with all three colors on one string lit, the noise is noticeable but ignorable … it adds an element of irritation. If I go to just one color lit (which, technically, is the load under bit modulation) the noise becomes nearly inaudible except very close. I have my fingers crossed.

![]()

Almost 100% done with the light tubes

Posted: 2005-August-11 Filed under: Lighting, Projects, The Bike With 2 Brains Leave a comment »I wired up the second light tube and had a case of deja-vu when I tried snaking it through the tubing: it was really tight and I kept breaking the wires I was pulling on. I used some silicone spray to try and get it going but it kept getting stuck. I eventually gave up, started on it the next day when I had some rest. I got it wired up and installed. I also found that I had a dead green LED in the original string so I replaced that. All I have to do now is to wire up the connectors … oh, and build the whole computer system.

![]()

The Savonius Windmill Generator

Posted: 2005-August-9 Filed under: Power Source, Projects, The Bike With 2 Brains Leave a comment »I decided that in this last week or so before I leave town, I'd pick up one more task: build a Savonius generator on the Bike With 2 Brains. So on Tuesday morning I got up and started thinking about designing it. I figured out that the bicycle seat posts are the right size to fit the "#608" size skate bearings — I had bought a pack of them because the 8mm hole is just a hair bigger than the 5/16" (7.99mm) threaded rod and bolts I planned to be using.

Wednesday I got up and started designing it in CAD. By 11 I came up with building a basic cube frame with a pair of centered cross-beams from side-to-side to hold the rotor. The key part is the detail below with the arm to hold the generator with a friction-coupling to the baby-stroller wheel (which is ultimately why I went with 5/16": it's the shaft diameter of the stroller wheel.) The diagram of this detail is below:

Basically, the rectangles on the left and right are the frame mounts and the center horizontal rectangle is the support bar. The small central circle is the bearing and the large circle is the baby-stroller wheel with the centered diagonal rectangle representing the 2×4 used for the rotor. The angled dimension lines surround the generator bar — the larger circle below the baby-stroller wheel is the motor housing and the smaller is the motor spindle (a wood dowel.) The line connecting the bolt (it's supposed to be a bolt and looks better in CAD zoomed in) is linked to the center frame by a spring.

I built a rotor that afternoon. The original one I designed had two problems: first, the shaft holes weren't well centered, and second, the top and bottom plates were not exactly parallel. I paid more attention to those two problems and things came out much better. I also used whatever remained of the vent pipe I had bought — it's just like the original prototype except that it's about 14" long. I even got the bearings mounted on the end and thought, "gee, that's it?" expecting it to be harder to make.

Thursday I got up and started working on the frame. I welded together a basic frame and rethought the cube shape: instead I went with a wide bracket for the rotor bearings and put the vertical members on either side of that. By that evening I had finish-welded the frame and tack-welded the brackets to mount the generator. It was almost hard to assemble it in the very light breeze because the rotor would spin so easily.

Friday I built the rest of the motor mount, mounted the preferred motor, and tested it against the fan in the attic — essentially the blower from a furnace. I was able to get about 4.5 volts open-circuit, 2 volts into 5 ohms (0.8 watts) and 1.5 volts into 3 ohms (0.75 watts.) I had to use a weaker spring than I started with because the friction of the stoller wheel against the dowel was too much when it was pulled tight. I don't know the wind speed nor the rotation speed, but it was pretty dangerous looking. I finished up the brackets and threw on some paint in the evening.

![]()

Mom and Dad stop by

Posted: 2005-August-9 Filed under: Exhibitions, Projects, The Bike With 2 Brains Leave a comment »I got to show off the bike to my parents. My dad brought a couple parts I asked him to make: stand-offs for the computer control box. He was particularly impressed that it works and comes apart to fit into the car.

![]()

A quick note about emergency lighting

Posted: 2005-August-8 Filed under: Lighting, Projects, The Bike With 2 Brains Leave a comment »I've been thinking about what would happen if the main battery went dead — the whole vehicle would go dark and silent. I had been thinking about adding separate markers on the steering tubes of the back wheels, but it would quite a bit of extra work. It dawned on me that I can set up emergency lighting with a relay and a couple batteries: as long as the power was on, the relay would stay on; if it shut off, the battery would connect to several of the lights on the string: i.e. far front, far rear, and the eyes … 6 lights at 20mA would be 120mA and would drain a 2200mAH battery in 18 hours, but if I got it down to say 10mA total, then it would last for 200 hours. If I went with green then it would be most visible. I dug up a very small relay with a 12-volt coil and it draws 15mA itself, but I found I could get it down to 7mA if I wired it in series with a capacitor (to let it latch) and a resistor (to keep it latched.)

I changed my mind and decided to make a pulse-width modulator with a low-power 555 timer and just hold the reset pin low via the control computer — if it failed, the 555 would start pulsing and drive the LED's.

![]()

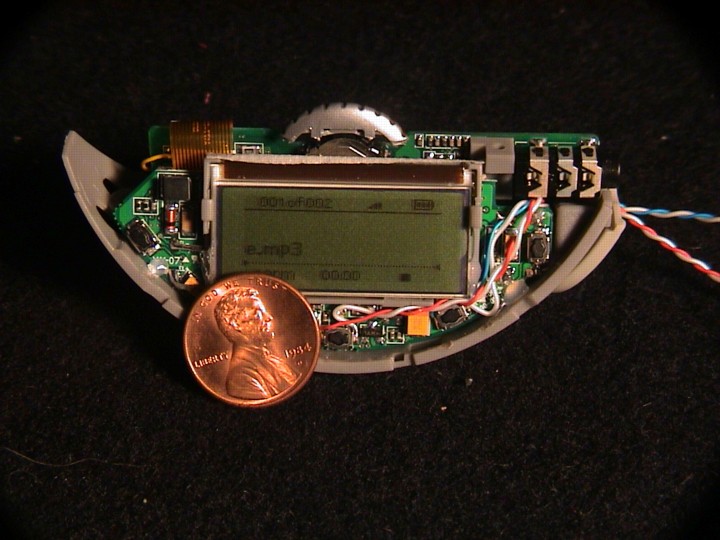

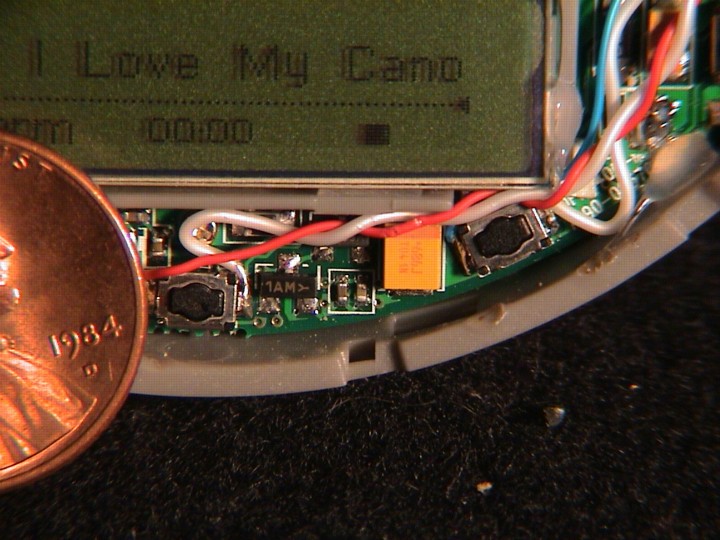

Hacking the MP3 player

Posted: 2005-August-8 Filed under: Audio, Projects, The Bike With 2 Brains Leave a comment »I took apart the MP3 player and did some measurements on the switches.

|

State |

Power button |

Play button |

|

off |

1.5V/0V |

0V/0V |

|

on |

3.2V/0V |

2.8V/0V |

|

playing |

3.2V/0V |

2.8V/0V |

It's pretty convenient that I can detect power-on through the switch voltages. Whew. For playing I'll need to check that there's some signal on the output which could be a bit tricker. I think I'm going to compare to some arbitrarily low voltage and run the comparator output through a diode to a capacitor. The capacitor would discharge slowly with a resistor through the base-emitter junction of a transistor: the collector could be attached to a resistor to 5 volts — while playing, it would stay very close to 0 volts (logic 0) but if there was no ouput, it would slowly rise to 5 volts, eventually tripping whatever logic input.

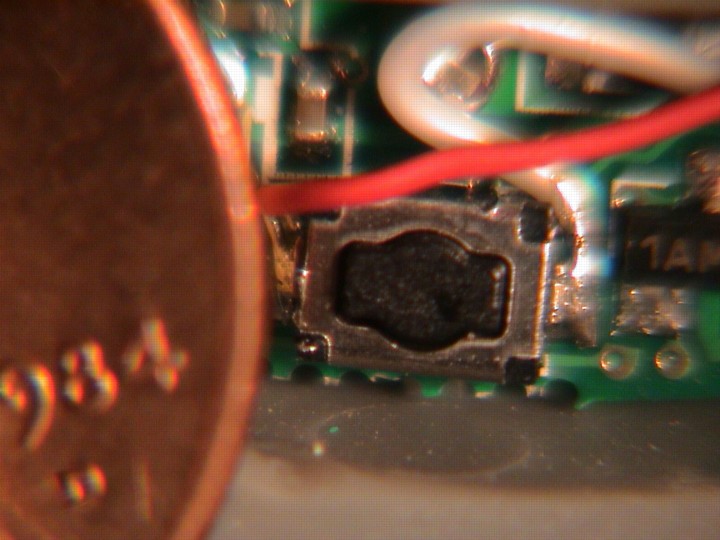

I wired up little wires to the switches and battery case to hook it to the logic circuits and power. What a pain to solder to this surface-mount stuff:

![]()

Finally sounds like it's working

Posted: 2005-August-6 Filed under: Audio, Projects, The Bike With 2 Brains Leave a comment »I'm using some DC-blocking capacitors to get the MP3 player output (which is grounded at -5V) to match the audio amplifier (grounded at -12V.) Unfortunately, I keep getting 1KHz noise from the switching supply. I tried going to the linear supply but that didn't work either. I even tried a big filter capacitor right at the MP3 player but no joy.

I figured out that the MP3 player was generating clean output but the speaker amplifier had issues with its ground being noisy. I tried a number of filtering techniques and such but came up dry. I decided to try with the LA4445 amplifier again: I figure I can bend the 2mm pins to fit the 0.10" spacing on the circuit boards I have. It dawned on me that I could probably make some kind of common-collector amplifier in a class A-B configuration.

I figure I can connect a resistor from emitter-to-base on each pole and one from base to a common input. The ratio of resistors defines the quiescent current and the values define the amplification. I may avan be able to do a push-pull with the 5-volt source for lower power and higher efficiency. I could set up the output to center around the -5V which is signal ground for the MP3 player. I thought about it for a while and decided to go with a common-emitter design with some biasing resistors and an op-amp — using the op-amp to compensate for the transistor switching.

First I tried the LA4445 because I thought it would be simpler. I spent an hour or so working, got everything wired up, but I took some shortcuts and the thing just won't work. Crap. Back to square one — again.

I decided to tinker with the transistors a little. I got to the point that I could generate output, but they won't stay on all the time in a true A-B configuration so it gets all noisy and such. I considered using some resistors and diodes to keep the transistors biased all the time.

I fianlly got a viable solution. I used the same crappy design I used for the amplifier I built years ago which just drives a couple opposed Darlington transistors with an op-amp as feedback, although I did a better job of fixing the high-frequency oscillation problem. It ends up drawing about 400 mA (5 watts) with the MP3 player in-circuit and the amplifier at volume with both speakers driven in parallel. I suspect that the output is around 2 watts total or so, based on around 2 volts RMS (as measured by the oscilloscope) into 2 ohms. If it hits 2.5 volts, it's at 3.1 watts which I think is about peak.

Based on the circuit I used, the input is already self-centering around the midpoint of the power supply. The transistors need 1.2 volts peak-to-peak to maintain quiescent current, so the theoretical maximum output (going rail-to-rail) is +/- 5.4 volts; RMS voltage is 3.8 volts or 3.6 watts into 4 ohms. I tried to get away with a single op-amp to do voltage gain and to power the main amplifier. It seems to work but is even more twitchy than before … although I guess the noisy volume level is so quiet that you'd have to be right next to the speaker to discern it. Here's the circuit:

I had an op-amp I was using to generate a solid signal ground, but I didn't need it so I took it out. Anyway, at the 12-volt source, the audio section (with the MP3 player draws about 50mA and when it's at full volume, it peaks around 200mA, so I assume the output power is around 1.8 watts total consuming some 2.4 watts at peak volume. It kind of sounds like crap with a bit of fuzzy distortion from the transistor switching noise — if you know circuits, it should be pretty evident why:

I got the amplifier wired and it works okay from the linear power supply but it's not working off the battery and I'm not sure why. It dawned on me that I can just use one of the op-amp's as a differential amplifier off the MP3 player and feed that into the prefabricated amplifier? I ended up with this simplified circuit:

The first experiment worked great so I rewired the circuit to take out all that extraneous crap to deal with the transistors and got it working again. It looks like I can get something like 3 watts of audio out of the thing, and the whole powered system typically takes around 2 watts at moderate volume.

It's just too bad I had to ditch the power transistors and heat sinks because they really looked cool.

![]()

Recent Comments